Today’s global landscape is volatile and unpredictable. From unpredictable natural disasters to escalating geopolitical tensions and unforeseen emergencies, business disruptions are not only frequent, but to be expected. Supply chain disruptions can be severe, having the potential to incapacitate supply chains, leading to delays, rising costs, and dissatisfaction from customers and regulators alike. Supply chain resilience, therefore, is not just a luxury, but a necessity.

Recent events have underscored how fragile traditional supply chains can be. Businesses that don’t take the time to prepare for supply chain threats or develop internal processes that are agile and adaptable will fall behind in reputation, profitability, and may even struggle to survive in this competitive landscape.

Whether your business is local and small or a large, multinational enterprise, adopting a proactive approach to supply chain resilience will be the key to mitigating risks and to gaining a competitive advantage. While business leaders may not be able to predict the future, by developing supply chain resilience, their businesses will be able to handle the supply chains risks that constantly emerge.

Step 1: Understand your supply chain and build relationships with your suppliers

As Carl Sagan famously said, “If you wish to make an apple pie from scratch, you must first invent the universe.” Similarly, to improve and strengthen your supply chain, you must first understand how it works. Start by mapping your supply chain, tracing all elements from raw materials to final delivery to the customer. This way you can understand where there are weak links or potential issues, from non-compliant suppliers, transportation bottlenecks, or geographic dependencies. Establish your company’s risk thresholds, categorizing and ranking potential risks, and institute regular risk assessments.

Then, get to know your suppliers a bit more, and use this information to make educated decisions about your suppliers. Your business may need to diversify its supplier base, or take steps to ensure that your suppliers are all compliant with relevant global regulations. Or, if you find a supplier is non-compliant or unreliable, you may choose to research and find other suppliers that could better serve your supply chain needs.

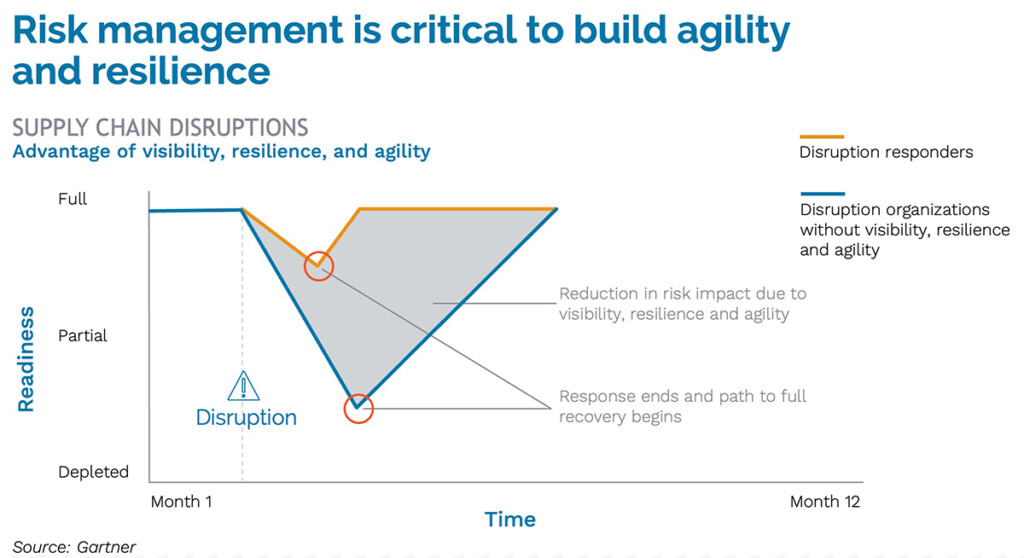

Figure 1: A balance of visibility, agility, and resiliency will in turn drive greater readiness in the wake of disruption

Finally, establish strong partnerships with your suppliers. Open communication and trust can enable greater flexibility during crises, and can assist in joint planning and risk management strategies.

Step 2: Invest in the right supply chain tech

Building supply chain resilience is not a manual task – it must be aided by technology. There are simply too many data points, coming from a vast amount of data streams from around the world, to keep up with and accurately analyze. Finding and implementing the right supply chain management tools and technologies is key to creating a supply chain that can weather both metaphorical and literal storms.