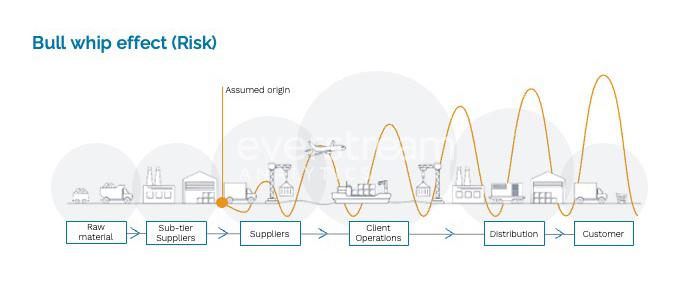

It isn’t just big, headline-grabbing events that hit companies and economies hard. Sometimes, even relatively small problems can ripple through businesses across the world. Small disruptions can be more disastrous than world events because of a lack of transparency: The events are often hidden so deeply in a company’s supply network that they’re invisible until their effects expand.

We can’t prevent global disruptions, but we can plan to respond quickly, efficiently, and effectively. Resilient, flexible supply chains help companies spot disruption before they feel its impact, and seize risk as a competitive advantage, wherever and whenever it occurs.

A resilient supply chain sidesteps disruption more easily, recovers more quickly, and outmaneuvers the competition.

7 tactics for supply chain responsiveness

As the impact of risk on global supply chains has grown, organizations are working harder than ever to develop resilient supply chains. Resilience is defined in part by how responsive the supply chain is to disruption, and how quickly it bounces back. The best approach for any one organization will inevitably depend upon numerous factors – from the nature of its products and production processes to its financial strength. But most successful approaches share these commonalities.

1. Gain a deeper understanding of risk

Many companies start their risk management efforts by trying to understand them. At its simplest, this is performing risk assessment to quantify the probability of a risk and its financial impact.

This two-dimensional approach has its place, and can be useful in helping companies to identify high-priority risks in their supply chains. But to be meaningful, these analyses should capture a richer picture of risk characteristics.

For example, consider adding further dimensions to your supply chain risk assessments, including the difficulty of detecting the risk up front, the lead time available between detection and the impact of the risk, the cost of recovering from a risk event, and investment required to put mitigation strategies in place.

2. Take a network-centric perspective

Supply chain risks can’t be fully understood without understanding the entire network they affect. At its simplest, that is intuitively obvious. A company needn’t spend too much time watching for disruptions at suppliers of simple commodity parts and materials, for example, if they can switch seamlessly to an alternative source in the event of disruption.

This tactic only works if you have sub-tier visibility throughout your entire supply network. If you know that your supplier’s supplier has a high risk of disruption due to pending labor strikes, you can work with that supplier to stock inventory before disruption hits. This approach can quickly become a competitive advantage if – as is the case in some emerging market locations – few alternative sources are available.

Supply network mapping plays such a critical role in supply chain risk that some risk management models focus on that more than the ability to quantify the probability or magnitude of specific risk events.

3. Make strong business continuity management the foundation

A responsive supply chain is based on strong business continuity management (BCM). According to the Business Continuity Institute, 82% of companies with effective BCM in place say that their programs have demonstrably mitigated the impact of disruptive events. Companies with the best supply chain risk management programs extend their BCM strategies outside the wall of the organization. They expect key suppliers to have their own BCM programs in place, and they conduct regular checks and audits to ensure they are.

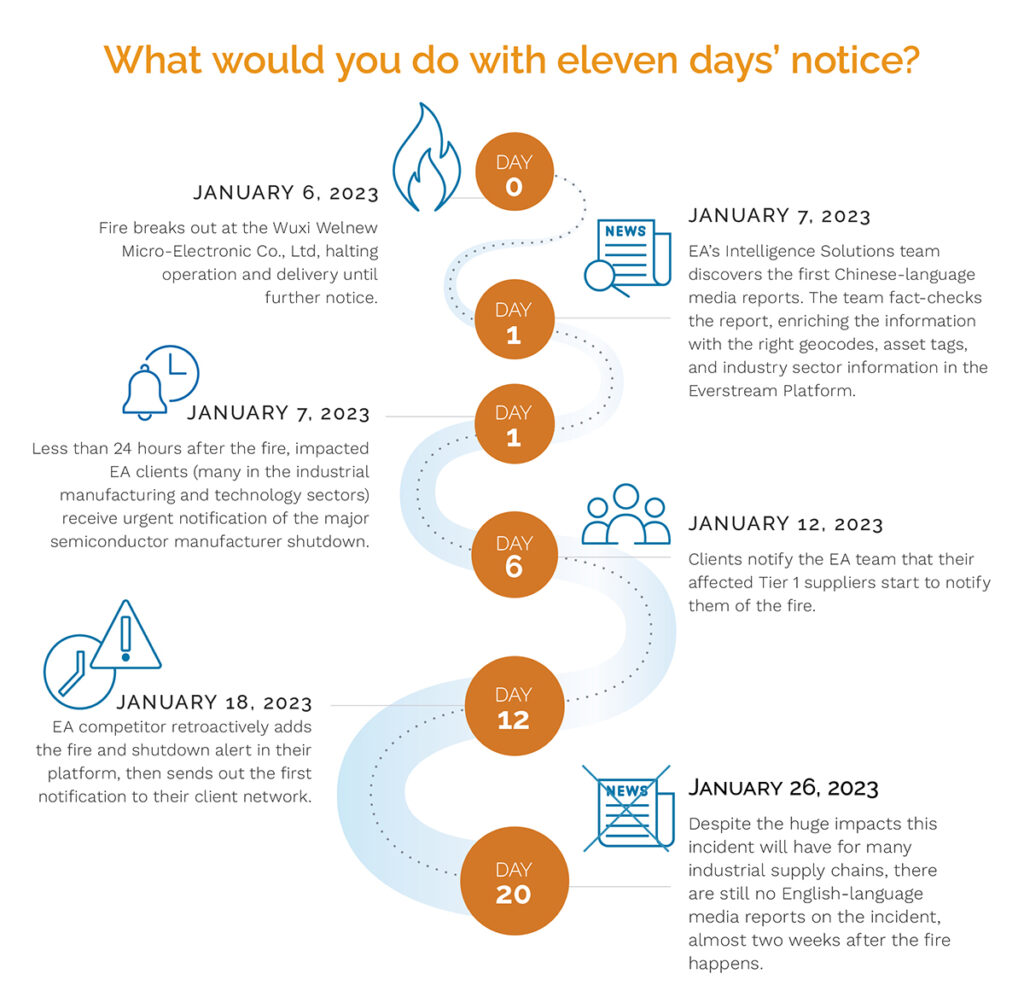

4. Responsive supply chains use all available data

Organizations with an earlier, clearer view of potentially disruptive events in their supply chains can respond more quickly and effectively. Leading companies use technology for the systematic collection and analysis of supply chain risk data. The best companies use multiple data sources – from external data providers, public sources such as social media, customers, and suppliers as well as their own staff – and they invest in smart tools to sift through that data to spot potential issues early.

The very best organizations integrate risk data insights into their everyday operations management – for example, increasing target inventory levels at national and regional distribution centers as customs delays increase waiting times at border crossings.

5. Collaborate within and beyond the organization

Clear communication and effective collaboration are vital if companies are to spot, avoid, and respond to supply chain risks. That means strong collaboration within the organization. Leading companies often set up cross-functional war rooms or control towers to manage supply chain disruptions. It also means close collaboration with customers and suppliers. You may even consider adding a supply chain risk opportunity manager to the team.

When management consultancy PwC asked more than 200 companies what they felt to be the most important enablers in supply chain risk management, alignment between supply chain partners was considered a top priority by the largest number of respondents, closely followed by internal alignment and effective information sharing.

6. Build in resilience

A rapid, well-coordinated response is essential when supply chain disruption strikes, but the effectiveness of that response is decided by steps the organization has put in place months or years earlier.

The best companies configure their entire value chains to reduce risk and promote resilience, using strategies like dual sourcing for critical components, flexible product designs that permit component substitution, or postponement techniques that allow inventories of unfinished products to be allocated to different end uses according to need. Leaders build resilience into their logistics processes in the same way.

Segmented transportation modes allow them to ship products faster to high-priority customers in normal operations, for example, while creating alternative routes when problems strike.

7. Create the right culture

Leading companies recognize that strong supply chain risk management is as much about culture as it is about processes. They work hard to ensure that employees focus on risk reduction alongside their cost, quality, and delivery targets.

They drive commitment to supply chain risk programs with strong support from senior management. And they reward their staff for measures that prevent supply chain disruption from occurring, not just for heroic work to fix problems that have already happened.

Non-responsive business strategies that increase risk

There are several common business strategies that tend to make supply chains more efficient, but they raise the level of supply chain risk. Here are five common business management practices that increase disruption’s impact:

Outsourcing – more outsourcing generally means a higher risk of disruption as well as an increase in quality-related risks as more activity falls outside the direct control of the end-product manufacturer

Specialization – companies increasingly tend to focus on certain tasks where they have a competitive advantage. This necessarily leads to increased outsourcing of other tasks, and can increase their exposure to disruptive events.

Digitization – makes supply chains more vulnerable to cyber threats.

Homogeneous strategies and business models – disruptive events are likely to affect many players in each sector, making it hard to find alternative sources of supply in the event of disruption.

Competition intensity – generally increases the urge to prioritize cost minimization over responsiveness, leaving companies slow to respond to disruption.

Leading companies have developed a holistic view of supply chain risk management. This means that the strategies and targets of the procurement and risk management division are intertwined; ideally there is only one organizational unit responsible for supply chain risk management. In the optimal scenario, risk management perspectives are embedded in the purchasing process, and supply chains are designed with an explicit risk-management focus.

Full supply network visibility leads to responsive supply chains

For any company seeking to improve supply chain responsiveness, the first step should be a focus on supply chain transparency. Companies need risk forecasting and then real-time monitoring as events unfold. But when a company has 10x or more sub-tier suppliers at each level of their supply chain network, this level of transparency quickly becomes overwhelming.

However, transparency can be managed by IT tools that enable companies to perform thorough supply chain mapping, risk analysis, and ongoing risk monitoring. Supply chain risk management software can help companies identify and assess risks, and gives the opportunity to react rapidly in the case of an event. In addition, companies can identify and implement the necessary physical supply chain risk management measures and business continuity management processes. In the optimal scenario, risk management perspectives are embedded in the purchasing process.

Companies should be aware of their Achilles’ heels so that they can prioritize parts of their supply chain. In that context, companies should begin with their most profitable products (on an absolute basis). As it is easily possible to become lost in an ocean of details, it makes good sense to concentrate on those products where supply chain disruption would have the biggest financial impact.

While advanced companies use supply chain risk management software, and have even adjusted their incentive schemes to implement this holistic view of supply chain risk management, there are still companies that have barely started down the technology path.

The best companies configure their entire value chains to promote resilience, using strategies like dual sourcing and postponement techniques.

Supply chain risk management monitoring gives companies a simple, yet rich initial view of overall supply chain risk. Aggregate measures give them an at-a-glance picture of overall risk levels in their networks, and allow them to quickly drill down to identify key areas of risk by geography and risk type. This can be achieved without relying on auditing and surveys, which can leave room for subjectivity or a lack of transparency on the part of a supply chain partner.

As companies evolve their supply chain risk management strategies, the model can be further tuned to account for mitigation efforts at particular nodes.

The approach can also be used to simulate alternative network configurations, allowing companies to consider the risk impact of proposed future developments. For example, in the total cost analysis of a supplier or a hub location, the customer can weigh the cost saving of a particular location in a low-cost manufacturing country against a possible increase in risk, exposure.

How responsive supply chains earn a valuable return on risk

Smarter supply chain risk management is a very effective insurance against the costly and long-lasting damage that disruptions can cause. But if they are built into an organization’s everyday operations, good risk management practices can provide plenty of other benefits, too. Once companies understand and control the real risks in their supply chains, they can often reduce costly buffer stocks.

When one consumer goods company conducted a risk assessment of a key distribution lane using Everstream’s Reveal platform for example, it was able to reduce logistics lead time by 30%, and to cut buffer stocks by the same amount. Client surveys suggest that, on average, resilient supply chains carry 14% less buffer stock than their more fragile counterparts.

Ensuring critical components are available from more than one source can increase flexibility in the event of “positive” challenges, since there is more spare capacity to meet unexpected peaks in demand. An ongoing relationship with more than one supplier can also benefit procurement efficiency, helping companies negotiate more favorable prices or allowing them to switch volumes between suppliers in different regions in response to currency locations or changes in those suppliers’ underlying costs.

Flexible manufacturing strategies, such as postponement or multi-product production facilities, similarly help companies to meet everyday demand volatility as well as supply issues. For example, many companies in the food and beverage sector now routinely adjust product formulations depending on the price and availability of different ingredients.

Greater transparency and clearer communication can also lead to upside opportunities as well as helping in problem management. A fuller picture of an organization’s second and third-tier suppliers, for example, can reveal that the end customer has opportunities to obtain components or materials at an advantageous cost, thanks to its scale or existing commercial relationships. Or companies may find that their own specifications or ordering practices are driving up suppliers’ costs, creating opportunities to improve end-to-end processes and share the savings.

Get our eBook to see how to calculate the value of supply chain responsiveness