You may not know exactly how much your operation overspends due to the bullwhip effect, but every time your team goes into operational crisis mode it takes significant resources to recover. And the later you identify risks, the more money you spend adjusting your supply chain to respond. However, by incorporating risk into demand and supply forecasts, and by catching disruptions before they grow, you can reduce the likelihood of experiencing the bullwhip effect.

What is the bullwhip effect in supply chains?

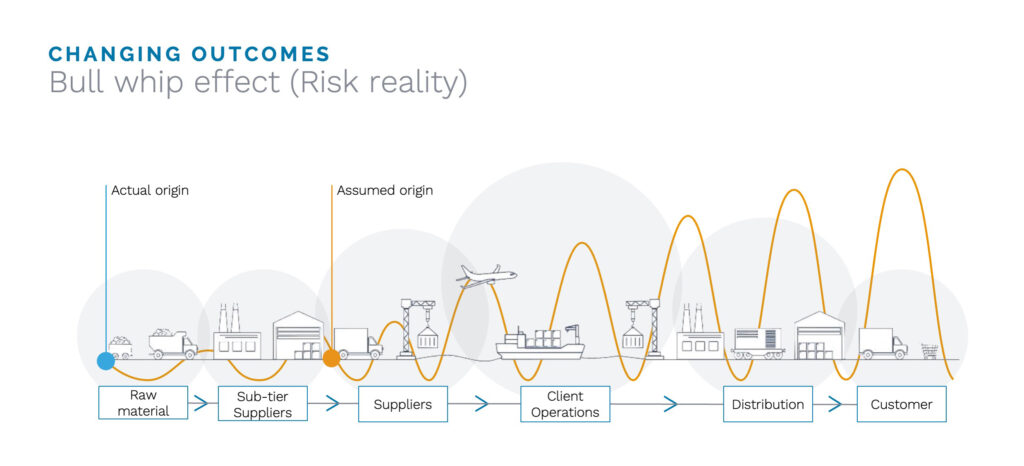

The bullwhip effect happens in supply chain when small changes in sourcing can lead to major shifts in downstream production. As shortages or delays travel down the supply chain, their effects can become magnified, much like the motion of a bullwhip being cracked. Factors such as poor coordination, inaccurate forecasting, and lengthy lead times can all contribute to this effect, resulting in issues with inventory or production due to unsynchronized quantities.

Why the bullwhip effect costs supply chains money

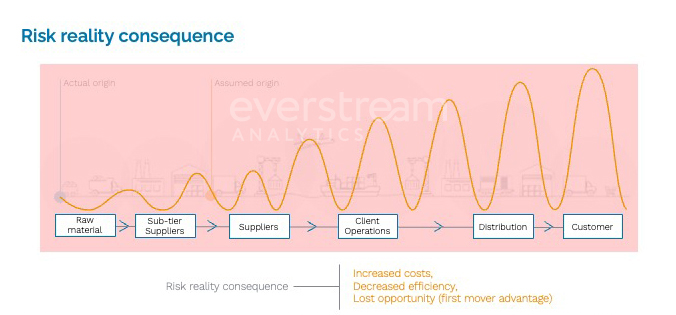

As risk moves forward in time, the magnitude oscillates greatly. Instead of catching risk early, most operations pick up on a risk somewhere along its journey, after its impact has already grown.

For example, by the time the average operation learns that they can’t get a component because their supplier’s supplier went out of business, it’s too late to seamlessly shift to an alternate plan. Instead, they will spend time and money researching and onboarding a new supplier, and may have costs for expediting materials or missing delivery deadlines.

Companies have spent fortunes over the years just focusing on demand and managing forecast accuracy, and today there is a lot of emphasis on scenario capabilities. But those scenarios only work if they are based on the best forward-looking information.

Effective risk management can help smooth out forecasting and planning to avoid this bullwhip effect.

Mitigating the bullwhip effect

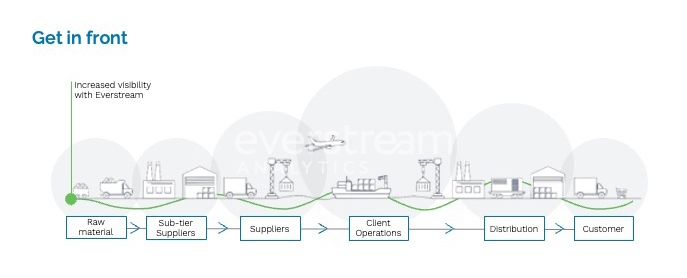

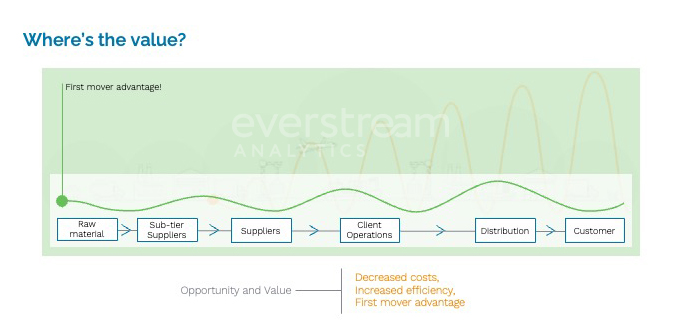

When you work to proactively mitigate the bullwhip effect, disruption doesn’t grow enough to throw off forecasting and planning. Instead, risks are identified and scored so that supply chain managers can pivot to alternatives early, keeping costs low.

The more you change plans, the higher the cost. That’s the reality. But identifying and mitigating that risk early in the planning stage saves cost and inefficiencies.

How proactive risk mitigation pays off

Spotting risk early and incorporating it into planning creates a first-mover advantage. A company that can secure resources earlier than its competitors, whether those resources are trucks or human beings or materials, gains a valuable competitive edge.

This end-to-end view of risk helps companies better understand their product and production facilities, and inbound/outbound deliveries.

Companies also avoid the angst that goes with the back-end issues of managing risk. Instead, risk is identified and mitigated throughout all stages of operation: planning, sourcing, making, delivering. Companies that spot risk early make faster, better, and more agile supply chain decisions.

A powerful, risk-management platform helps reverse the bullwhip effect

Everstream’s risk management platform takes multiple data sources and turns those into insights and then overlays those insights onto each company’s individual supply network. With supplier discovery capability, the platform can risk-assess the entire sub-tier network and then monitor it, including client facilities and inbound-outbound processes.

Get our annual risk report to see what supply chain risks to watch for in the coming year