Supply chains involve many stakeholders, both internal and external. Internal departments involved in supply chain activities include finance, procurement, governance, risk and compliance, customer and supplier relationship management, and manufacturing. External partners might include a range of suppliers, distributors, carriers, logistics providers, sub-contractors, and customers.

Each of these internal and external parties may use their own, disparate, IT solutions. This presents a significant hurdle for companies looking to optimize their supply chain operations, whether operationally (managing inbound, outbound, returns, etc.) or strategically (evaluating how changes to their operations might create benefit in terms of cost reductions, lower carbon emissions, or improvements in customer service).

By deploying supply chain risk management software, companies can connect the dots and not only monitor their supply chain end-to-end, but also leverage prescriptive recommendations based on predicted risk at every step.

A look inside how supply chain risk management software works

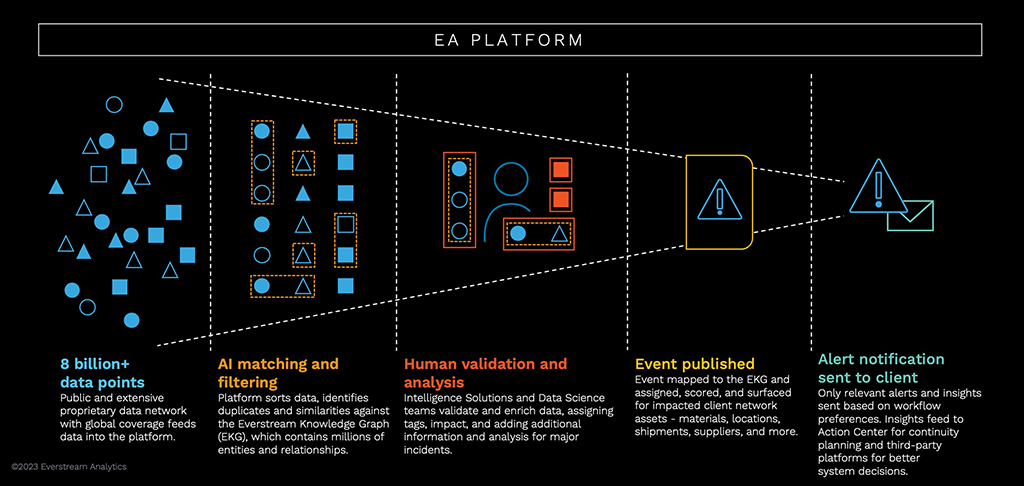

The basis of supply chain risk management technology is a cloud-based software platform that combines multiple sources of data from different supply chain participants. That might include confirmed data from sub-tier suppliers; operational, performance, and cost data from external service providers such as transportation companies; financial status of suppliers, relevant information on weather conditions, political unrest, regulations, or other geographic supply chain risks.

Importing and integrating these various data sources is automated with regular updates, and reviewed and fact-checked by human intelligence to ensure that organizations always base their decisions on the most up-to-date and relevant information available.

Figure 1: Everstream’s supply chain risk management software process.

Update frequency depends upon the organization’s operational requirements and the availability of new source data. Delivery status information from a third-party logistics provider might be updated every few minutes, for example, while new information on marine vessel movements might only be available every few hours, and labor action updates every few days. The data used to model changes in the supply chain network or operations, on the other hand, might be handled more periodically.

The software platform uses this rich and granular data in several different ways. It can provide detailed dashboards to supply chain management teams, allowing them to see the overall status of their networks at a glance, or to drill down into the details of specific locations, nodes, routes, or materials. It can monitor supply chain operations and automatically trigger alerts for suppliers whose operations are at certain risk levels, or shipments at risk of delay.

The value of intelligent analytics

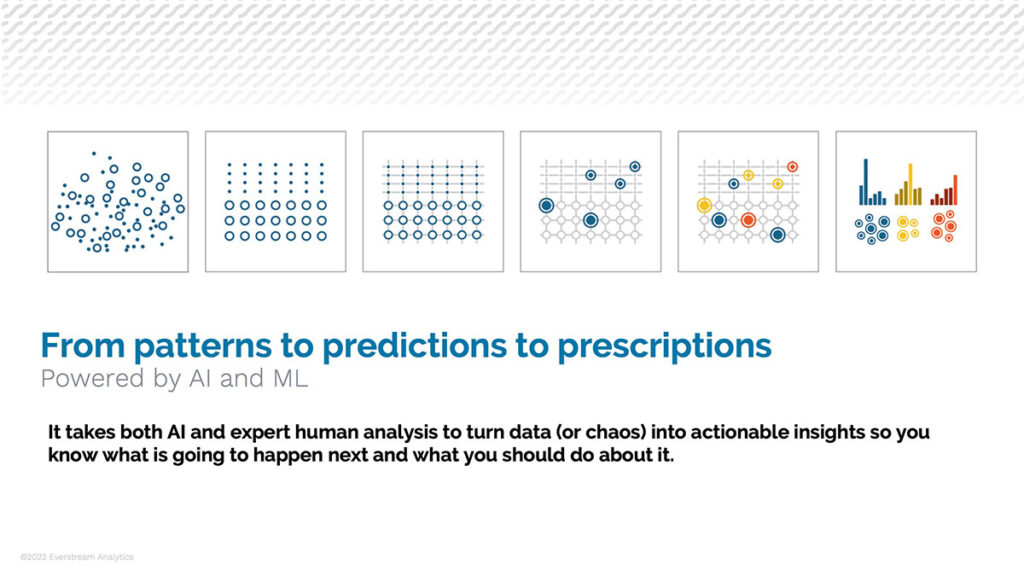

Artificial intelligence and predictive analytics can handle massive amounts of data, but it also presents it in a way that makes sense without having to manually manipulate it to understand it. The whole point of this technology is to provide instant insight to speed decisions – decisions that can prevent shipment delays or damaged cargo. It reveals trends, offers trustworthy recommendations, and paints a complete picture, even as that picture constantly changes.

It’s invaluable to know ahead of time what risks are most probable and preventable. For example, supply chain risk management software for logistics automatically analyzes every shipment, type of freight, mode of transportation, and planned lane and then overlays weather, temperatures, infrastructure outages, live traffic patterns, social hazards, etc. along the entire route. It can then score each risk and flag those risks that need to be prioritized, even offering mitigation recommendations to speed decisions even further.

For procurement, supply chain risk management software can analyze a company’s entire sub-tier supply chain network to identify a high risk of cyberattack or insolvency for a particular supplier. It can also predict a high risk of supply interruption for a raw material in a politically unstable geographic location. In both examples, relevant risk scores offer a company advance notice for shifting to other supply options.

These insights not only give every shipment the best possible chance of being delivered on time and in its expected condition, but it can also save companies money. For instance, companies without this type of analytics would likely pay extra for suddenly scarce materials, for supply redirects, or for reefer trucks for sensitive cargo because it’s what they’ve always done.

On the other hand, a company using this type of supply chain risk management software would be able to use risk to its advantage. With advance notice of emerging disruption, this company can purchase supplies before price increases, switch suppliers before insolvency announcements are made, or redirect shipments around a soon-t0-be-closed port.

Similarly, a company without this capability may not have much notice of a tropical depression that was supposed to go east but a day before the shipment headed west. With the software, however, logistics leaders would have all shipments coming from, going through, or heading to the danger zone scored in real-time so they would have the time to modify routes and set the proper expectations.

Supply chain risk management software now powered by artificial intelligence

We are seeing artificial intelligence and advanced analytics everywhere these days including in supply chain. According to Gartner, the trend of transition from legacy tools to solutions that rely on this more sophisticated supply chain technology will only increase in the coming years. Artificial intelligence is a game-changer because, as Gartner puts it, “AI supports the shift to broader supply chain automation that many organizations are seeking. For example, AI can enhance risk mitigation by analyzing large sets of data, continuously identifying evolving patterns, predicting disruptive events along with potential resolutions.”

Artificial intelligence can do what humans simply can’t, at least not nearly as efficiently: gathering and assessing massive amounts of dispersed data that is changing at lightning speed, and providing actionable analytics that gives decision-makers insights they never had. AI capacity is nearly limitless, especially when combined with human expertise to guide, filter, and fact-check the computer results for relevance.

Figure 2: A combination of artificial intelligence, machine learning, and human analysis power best-in-class supply chain risk management software.

When supply chain risk management software is powered by artificial intelligence, managers can do more sooner and faster. Decisions aren’t based on old, unreliable, or incomplete data but accurate, historical, or real-time data that’s already been analyzed. It’s saving leaders massive amounts of time and resulting in more proactive and appropriate actions. The newfound capabilities are too attractive for many to ignore. In fact, Gartner reports that nearly a 270% increase in AI implementation over the past years, with 40% of organizations saying they’re using it to some capacity.

Beyond artificial intelligence, advanced analytics is also playing a major role in the advancement of supply chain risk management software. For many, this means predictive analytics that can provide forward-looking estimations that are highly accurate. Gartner says that the value of advanced analytics is to help organizations “identify data patterns and anticipate future scenarios – as well as prescriptive analytics – a set of capabilities that finds a course of action to meet a predefined objective.”

Technology gives business leaders unprecedented, actionable intelligence to assess, identify, analyze, and mitigate risks up and down the supply chain. Instead of relying on legacy applications that can’t keep up with the amount of data or spreadsheets that are labor-intensive and historical, supply chain risk management software is enabling businesses to track weather patterns, infrastructure and traffic issues, environmental, social, and governance issues (ESG), natural disasters, and temperature fluctuations with great accuracy. With this data in hand days and even more than a week in advance of a shipment, leaders can make smarter decisions about the best way to mitigate risks.

The increasing cost of manual supply chain risk assessment

We all know supply chains are full of risk. While the industry is growing rapidly and Gartner believes the trend will only increase, not all companies are ready to adopt a new way of doing things. If it works, why fix it?

Forrester has a different perspective, saying, “Executives must take big bets on new technologies, business models, and emerging markets to stay ahead of the fast pace of competition.” Change is scary but falling behind can be a death sentence. Now that the value of artificial intelligence, predictive analytics, and prescriptive analytics is well-documented, it’s only a matter of time before this technology becomes the new norm.

With the pace of production and shipping increasing, companies must up their game. Delays can mean lost revenue, customers, and fines if they have on time in full commitments. Relying on manual efforts, unintegrated systems, and inefficient processes slow down the supply chain. The amount of data needed to effectively manage risk renders these traditional methods obsolete.

The ROI of supply chain risk management software

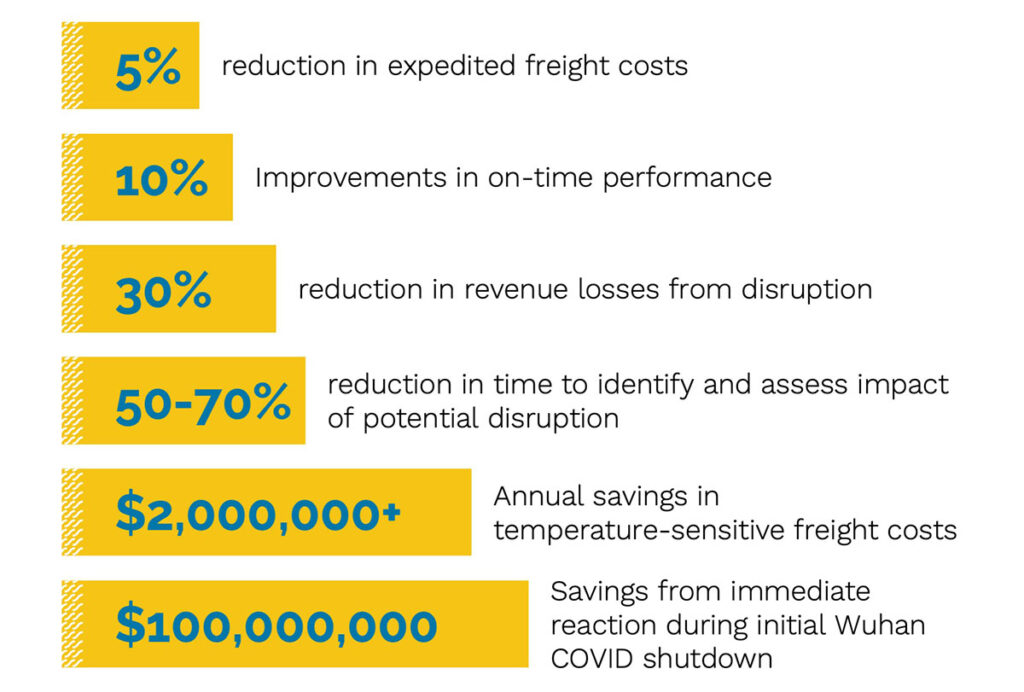

Beyond the obvious operational benefits offered by greater transparency, the real power of supply chain risk management software comes from the application of advanced analytics tools to derive new insights from the data. The combination of rich, timely data and advanced analytics capabilities translates into real value for companies in several ways:

- Identify your suppliers’ suppliers and pinpoint their actual manufacturing locations. With AI-powered predictions, you can anticipate high-risk events from weather patterns to material shortages to supplier viability and visualize multiple tiers of business and supplier relationships down to country of origin.

- Gain real-time data to know which products and revenue are at risk to make decisions faster. Monitor suppliers’ flow of materials and components to uncover multiple risk factors, better forecast performance, and assess the possible business impact.

- Get predictive insights from current events and historical data to show supplier, facility, and material risk.

- Uncover supplier signals indicating financial, sustainability, compliance, and reputational risk to make alternative decisions.

- Gain better functionality of procurement, logistics, and other supply chain systems by feeding risk data into your control tower, TMS, ERP, and SCRM, so your existing data is part of your workflow.

Figure 3: Savings and improvements realized by clients after adopting Everstream’s risk management platform.

Supply chain software cuts through complexity too, allowing management resources to focus on the parts of the network that face the greatest risks, or which offer the biggest improvement opportunities. It allows data-driven decision-making as companies seek to balance costs, risks, and environmental impact.

Be proactive instead of reactive

Spreadsheets are static. Legacy systems can’t keep up. Companies that want to get control of their risks require a dynamic system that automates the entire process. Supply chain risk management software with intelligent analytics is capable of consuming large amounts of data at scale. It then simulates various scenarios with forecasted conditions and risk scores included so leaders can determine which risks warrant action.

Instead of rushing to action with every potential risk, leaders can evaluate their options before changing a supplier, a mode of transportation, or a date. They have reliable, real-time data they can rely on to make an informed decision as much as 10 days before the shipment is scheduled.

In other words, supply chain risk management software enables companies to shift from a reactive to a proactive management approach. Supply chain risk management software provides the data and analytical capabilities necessary to optimize supply chain network design and planning. By combining a company’s own data with external data sources encompassing supply chain risk, decisions can now be based on empirical data rather than “gut feel.”

Because best-in-class risk management software incorporates every Tier-n supplier, it paves the way for a more collaborative approach to supply chain management, in which participants work together to overcome challenges and deliver the highest possible level of performance.

Get our eBook to calculate the value of deploying SCRM software in your operations