Commodities are the heart of any thriving supply chain. Products don’t simply appear out of nowhere, after all. As a result, interruptions to commodity sourcing and transport can be difficult to recover from quickly, especially if your company or your supplier is caught by surprise.

It’s important to understand where your commodities come from so you can avoid costly delays, disruptions, and avoid brand damaging sustainability issues. Tracking raw materials from the source may seem time consuming and confusing, especially considering some commodities are produced half a world away and through complex and obscured supply chains. However, monitoring your key commodities will help your organization stay compliant to new and existing regulations, allow your supply chain managers to plan and make decisions effectively, and even gain first-mover advantages.

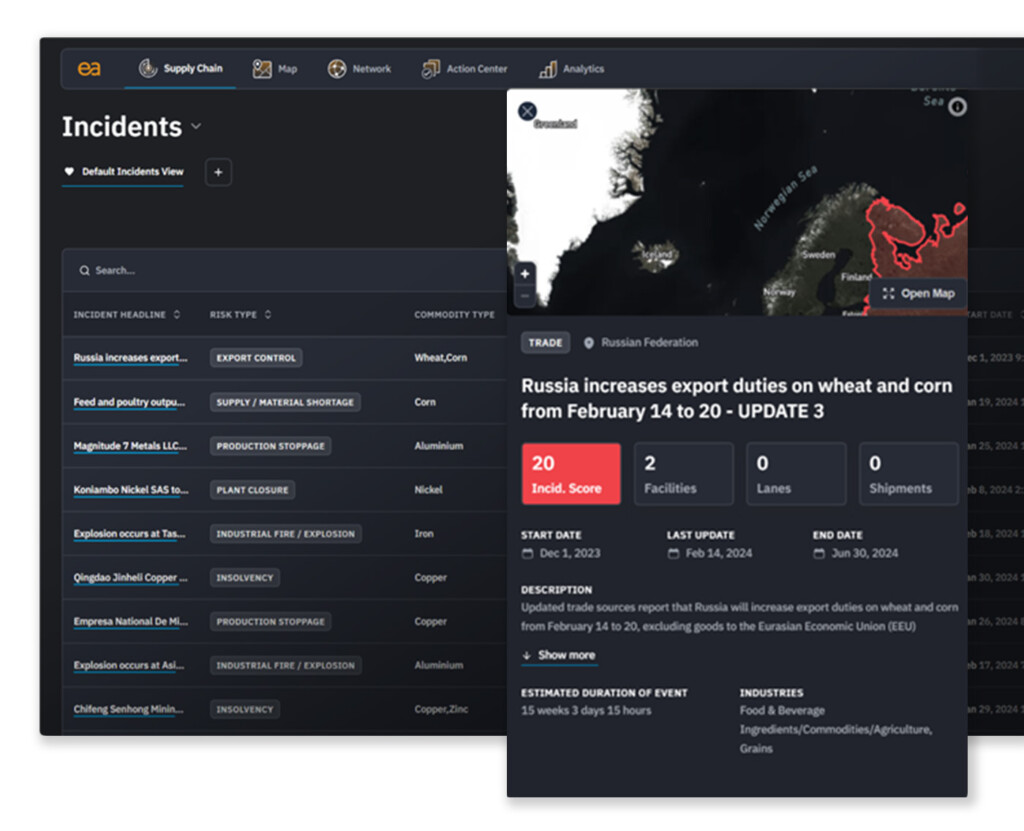

Today’s tools make it easier than ever to track raw materials across the world, so make sure you’re setting your organization up for supply chain success.

What is commodities monitoring?

Commodities, or raw materials, are the basic building blocks of any product. They are key to production, and therefore present major risks to a business if their normal supply chains are disrupted. Monitoring the commodities that are central to your business’s product operation should be a significant part of your overall supply chain management strategy.

To effectively monitor the state of your commodities’ supply chain, your business should focus on the sources and quality of your raw materials. These insights will give your company early detection abilities in the case of unexpected disruptions, such as inclement weather or an evolving geopolitical situation. Additionally, tracking your commodity inventory levels will give your company early awareness of any potential critical gaps in available capacity.

Why monitoring commodities is important

Monitoring commodities isn’t just important, it’s critical. Imagine trying to make your products without the materials that make them up – how long would your business last without access to those components? Customers will not put up with delays, and if it happens they will also want to know that you can confidently predict when a delay due to materials shortage will be resolved. Especially now that technology to do so is available.