With supply chains more interconnected now than ever before, international logistic operations are getting riskier. Climate change will continue to engender unexpected weather events that can derail transportation or keep ships in ports. Increasing regulation aimed at facilitating net-zero emissions for companies and countries will put a further burden on businesses trying to balance their bottom line, customer satisfaction, and climate-consciousness. And ongoing geopolitical situations are highlighting the volatility of certain shipping routes, manufacturing processes, or supplier locations.

These three factors will significantly shape the future of international logistics. Concerns as complex as these can’t be ignored. It is imperative that businesses understand the impact of these risks on their logistics and proactively put mitigation strategies in place.

Unexpected weather risks in international logistics

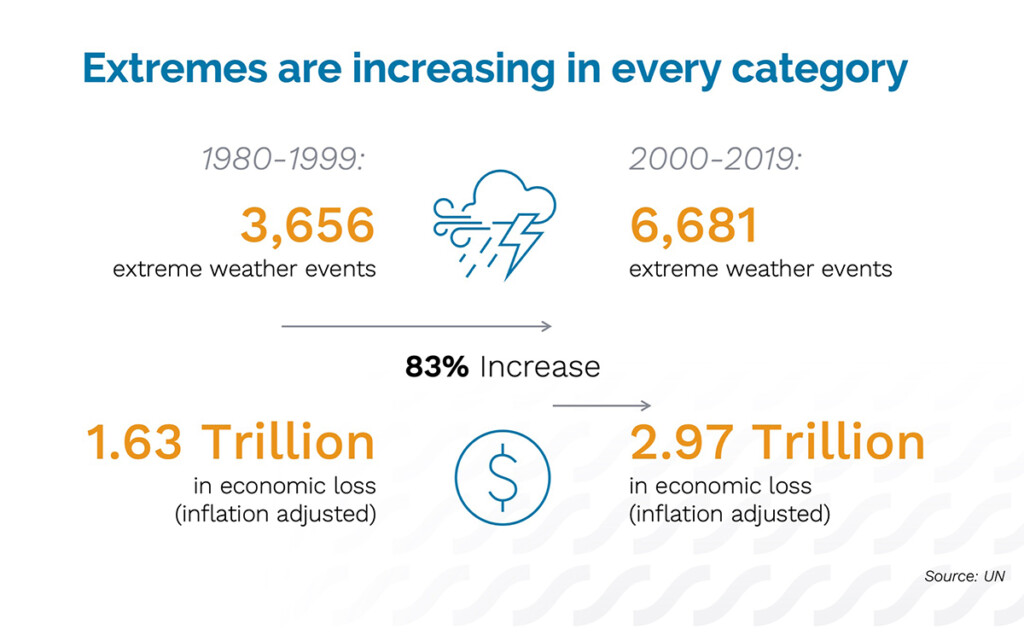

Unexpected floods, droughts, and hurricanes, oh my! Climate data is clear – we’re now experiencing weather extremes with volatile frequency and intensity, severely disrupting supply chain logistics. The U.S. experiences weather events that cost $1 billion in damage every three weeks, up from approximately three times a year in the 1980s. There’s no question that climate change is a major problem for supply chain logistics.

Figure 1: Weather disruption is the top risk to logistics in 2024, costing supply chain significant losses in revenue and delivery timeframes (source: Everstream Analytics).

It can be difficult to conceptualize how to mitigate against a risk that is, by nature, very erratic. While some storms might have a few days of lead time – still not a lot, given the lack of agility in most logistics operations – some weather events may require quick thinking and informed decision-making.

Take a look at your current supply chain logistics and think about where your key operations or transportation centers are located. Are they located somewhere that is prone to natural disasters, or are there key places within your supply chain that have seen unusual weather patterns, such as an increase in droughts or floods, or extreme heat or cold? Are your typical transportation lanes impacted by hurricanes, storms, or other weather disruptions? Finding the best mitigation strategies and putting flexible contingency plans in place will be crucial to maintaining smooth supply chain logistics in the face of inclement weather.

Net-zero target risks in international logistics

Countries and businesses alike are looking to address climate issues with new net-zero focused legislation, targets, and pledges. There is also an increasing consumer push to favor companies that are more eco-friendly. While net-zero targets may be difficult to immediately meet, now is the time to find what works best for your company to reduce emissions throughout the logistics process.

LEARN HOW TO BALANCE LOGISTICS EFFICIENCY AND RESILIENCE IN OUR NEW WHITE PAPER: DOWNLOAD NOW

For example, companies that rely heavily on one type of transportation, such as air freight, may find that switching some cargo to ground shipping instead might help them lower their emissions. However, this will likely make the logistics process take longer and will require adjustments in the quantity of materials or products shipped or stored at any given time. Furthermore, geographical considerations will come into play, as shipping requires drayage yards or ports with open slots, and, ideally, short wait times. Finally, this may also require a change in regular regulatory operations to ensure that companies meet compliance requirements.

It may take some time for businesses to get their net-zero strategy right, so the time to start is now. Otherwise, companies will face both regulatory consequences and damage to their reputation.

Geopolitical risks in international logistics

Logistics operations are also vulnerable to geopolitical situations, which can evolve rapidly and seemingly randomly. Tensions in Taiwan, Russian cyberattacks on U.S. cargo companies, and the ongoing disruption by the Houthis in the Red Sea are just a few examples of geopolitical events that are having profound effects on international supply chain logistics this year alone. Similarly, new sanctions and tariffs can also interrupt regular trade flows, impeding a smooth supply chain lifecycle. And, labor strikes more frequently threaten to slow down trade, highlighted by last year’s dockworkers strike in North American West Coast ports. It doesn’t take much to disrupt global transport.

Sixty-four countries around the world, as well as the European Union, are holding elections this year. The results of these elections could impact global supply chains in various ways, depending on the specific context of each country. Businesses with international supply chains should keep an eye on these elections, and have mitigation plans in place for any specific geopolitical circumstances that may arise.

Managing international logistics risks

Each of the risks above could be considered a behemoth in and of themselves. Before continuous monitoring and advanced analytics, it was practically impossible to understand the full scope of these risks. There was no way to tell if mitigation or contingency plans were truly the best in each situation, or if they were just based on tribal knowledge, a hunch, and a hope.

Luckily, there are now several avenues that businesses can take when considering their risks in international logistics. There is now a lot of data available to compare the efficiency and pricing of alternative options to understand the fastest and cheapest ways to move freight. However, there is often a lot of volatility in transit times and costs when disruptions occur – making selecting from alternatives a choice between several bad options. To avoid this, companies should focus on reliability, as opposed to pure efficiency, when managing their supply chains.

What does prioritizing reliability look like?

It means choosing the more predictable option instead of the most expedient option. Proactively choosing dependable options gives companies much-needed wiggle room during an unexpected event. This priority shift can smooth operations in several areas:

On-time delivery. Choose shipping through calmer (although perhaps slower) waters serves as a necessary insurance policy against the volatility of extreme weather disruption.

Materials inventory management. Companies may consider nearshoring or storing an increased amount of stock nearer to customers, to keep the business running during manufacturing or logistical disruptions.

Carbon emissions compliance. Understanding which low-carbon shipping method works best for a product sooner rather than later means that supply chain managers can ensure freight capacity ahead of other competitors

Cold chain management. Spending more than needed on cold-chain shipping equipment and lanes can erode profits. Risk management data helps guide decisions on delivery dates, routes, and equipment for cold-chain shipping.

Port delays. Instead of routing to the closest alternate port, logistics managers can analyze the risk potential at all alternate ports and their transport connections, then chose those with lower risk.

International logistics will never be without risk – but every good sailor knows to search for smoother water when faced with impending storm. Understanding the risks inherent to international supply chains is key to creating strong mitigation and contingency plans that will give your business best options in the face of uncontrollable circumstances.

LEARN HOW TO BALANCE LOGISTICS EFFICIENCY AND RESILIENCE IN OUR NEW WHITE PAPER: DOWNLOAD NOW

Heather Kosztowny is the Director of Data Science for Everstream Analytics, leading development and implementation of transportation modeling and optimization insights. Her 15 years of experience in data analytics and modeling have focused on logistics issues and carbon emissions evaluations and insights.