Leading organizations are pursuing more powerful, intuitive, and integrated solutions to the challenge of supply chain risk, and deploying the supply chain Center of Excellence (COE) to get there. Supply chain managers are moving away from the reactive model of the past, in which every disruption is a new crisis and responses are created on the fly. Instead, their goal is to develop processes and capabilities to manage ongoing risks and disruptive events in the supply chain as part of day-to-day operations.

Organizational change is a journey. Here, we will outline a phased approach to the development of SCRM capabilities, with the CoE at its heart.

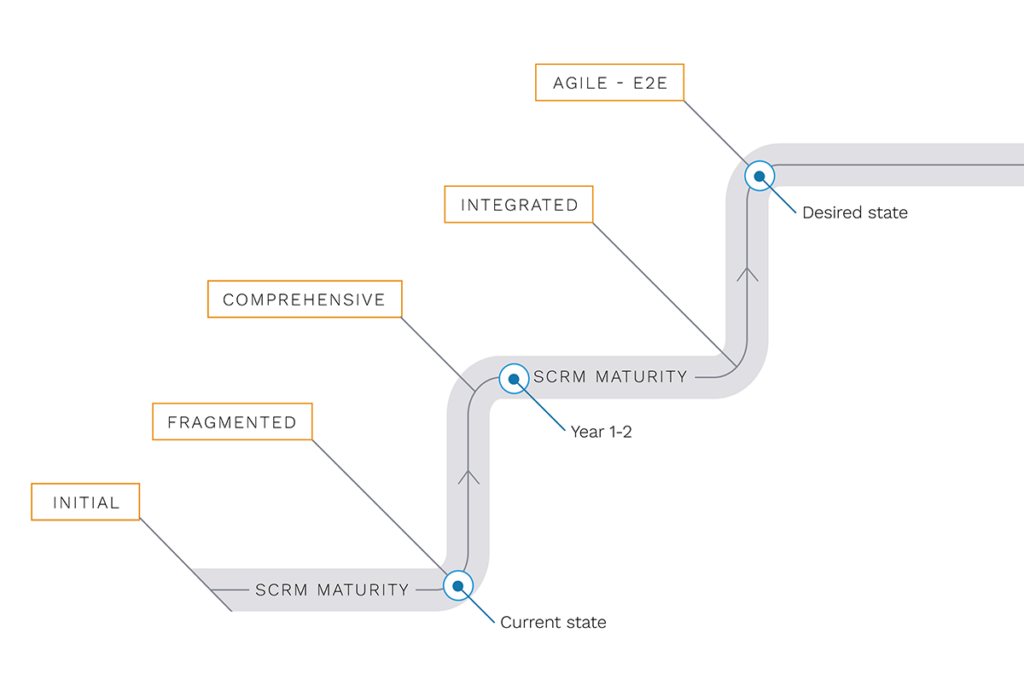

Figure 1: Everstream’s maturity framework demonstrates the path from a fragmented reactionary supply chain setup to an agile end-to-end supply chain management.

The agile supply chain center of excellence

Supply chain risk management is a specialized activity requiring detailed knowledge of risks and risk mitigation strategies, access to data from multiple internal and external sources, and the ability to analyze that data, gain insights, and determine appropriate responses. And building an agile and resilient supply chain is a complex change-management task, requiring the design and deployment of new policies and operating procedures, intensive cross-functional collaboration, and effective communication with multiple stakeholders.

Click here to download the full white paper

The fastest, most effective way to introduce those things into a business is by creating a dedicated organization to manage them: the agile supply chain risk management center of excellence. This new organization doesn’t need to be big: many SCRM CoEs begin with a single leader and grow over time to include a small handful of managers and subject-matter specialists. And because SCRM involves so much of the broader supply chain organization, centralizing key expertise in one place is much more efficient than attempting to replicate the same skills across dozens of teams.

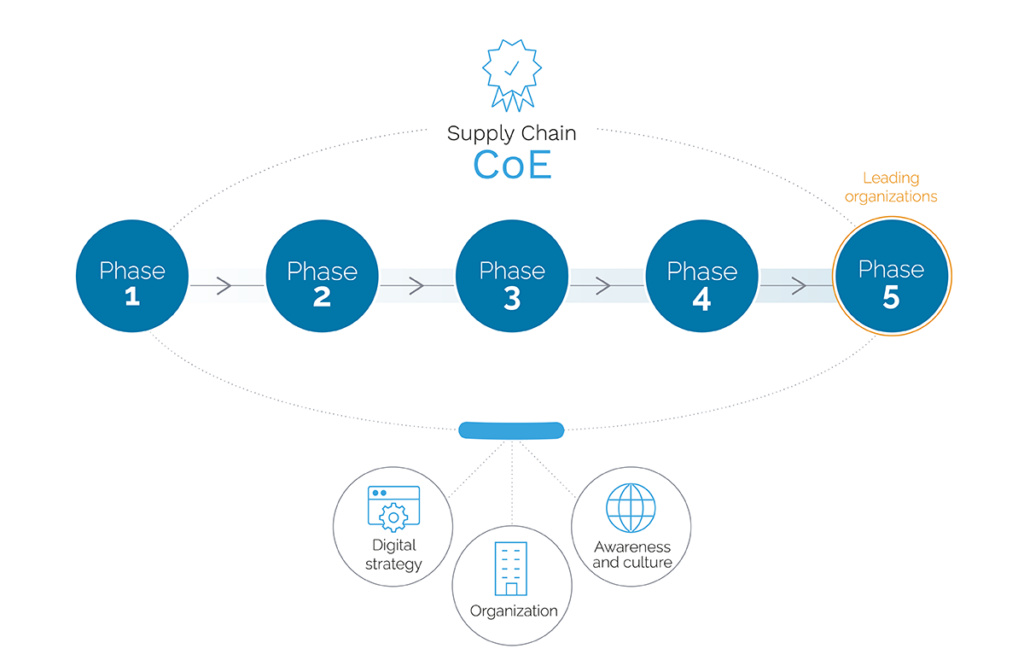

Figure 2: Agile Supply Chain Risk Management brings the whole organization together

The SCRM CoE plays a central role in developing risk management vision and strategy, establishing risk management processes and tools, and planning their deployment across the organization. Key activities include:

- Working with senior leaders to define a clear vision for supply chain risk management, which is aligned with the company’s overall mission and its supply chain management goals

- Establishing governance frameworks, communication procedures, and feedback mechanisms so SCRM activities can be monitored and improved over time

- Driving change-management activities to roll out and embed new processes, new tools, and a new culture across the organization

- Fostering cross-functional collaboration by establishing a supply chain risk management board, organizing update calls with key stakeholders, and managing metrics and dashboards to create transparency about the organization’s SCRM capabilities

When the rollout begins, the CoE supports end users as they adopt new approaches, manages communication and collaboration on risk topics, and tracks the organization’s progress toward its SCRM vision. Key activities include:

- Managing new digital tools and data sources that improve the organization’s awareness of risks and its ability to manage, mitigate, and respond to them

- Enabling SCRM adoption by integrating new tools and processes into existing supply chain systems and workflows, training and supporting users, and continually refining and improving the user experience

- Working across the business to identify, codify, and share best practices and assess the value of SCRM activities

Over time, the CoE gradually transitions into its end-state, which involves a mixture of direct, tactical support on risk management issues, and the continuous evolution of risk management strategy and processes. Key activities include:

- Crisis management in the event of supply chain disruptions

- Providing data and analyses to support complex procurement or network design tasks

- Evaluating new and emerging threats

- Introducing new tools and technologies

- Continually improving risk management policies and processes

- Getting there from here

If your risk management capabilities are not yet where you want them to be, you need a pathway to improve them. The first step in any change journey is an honest assessment of where you stand today and a clear vision of where you want to go. Leading companies often begin this vital work by nominating an executive to oversee the SCRM topic in the organization and establishing an SCRM CoE. At the outset, the CoE is likely to be extremely small. For the early phases of an SCRM transformation, it may require just one dedicated person with the drive, energy, and experience to build the function. That involves five broad phases:

Figure 3: Throughout a companies maturity development the SCRM COE constantly reevaluates its digital strategy, the organizational setup and the awareness and culture around agility, resilience and sustainability.

Phase 1: Pre-rollout

The first job of the CoE leader is to gather information from across the business, learning where the critical supply chain risk pain points are today and what key stakeholders expect from SCRM. A survey of senior managers is a good way to do that quickly. The leader should also have in-depth conversations with existing risk management specialists in the business, such as enterprise risk management and corporate security.

Once the initial data gathering is complete, the CoE leader can work with the senior leadership to draft a detailed vision for SCRM. This should include the key priorities of the function, its short- and medium-term targets, and its long-term goals.

Phase 2: Rollout for operations and systems

With a strong vision in place, the CoE can swing into action. Key tasks for the first phase of operationalization include setting up the organization’s digital SCRM platform and defining the major use cases for advanced risk management tools and analytical systems. This phase is also the time to establish governance frameworks for the CoE, begin the process of engaging with stakeholders across the business, and plan the change-management activities that will support the at-scale deployment of new SCRM approaches.

Phase 3: Rollout for internal customers

In the second phase of the rollout, the CoE will start to work with its customers across the organization. This will involve giving users access to new tools, providing appropriate training and support, and defining best practices for SCRM activities. That work can begin at a small scale while governance, stakeholder alignment, and change-management planning activities are still ongoing. This is often the point when the work of the CEO becomes too big for one person, and a second dedicated manager is brought on board.

Phase 4: Rollout to scale

In the third phase, the focus of the CoE shifts to the challenge of scale. It continues to bring new users on board at an accelerated rate, and it begins to quantify and track the value created by SCRM activities. As more stakeholders become involved in SCRM activities, the CoE also needs to ensure that different teams and functions are collaborating effectively, setting up dashboards, collaboration forums, and feedback mechanisms that allow a truly end-to-end approach to risk management in the supply chain.

Phase 5: Ongoing

After phase three, the SCRM CoE shifts into its long-term way of working. It will spend more time providing specialized services to the business, such as crisis management or advanced risk analytics. And it will continue to bring more stakeholders on board and support users in everyday risk management activities. By this stage, the CoE may have grown to a staff of four or five.

Those staff numbers are based on a mid-sized company of around $10 billion in revenue. Other organizations would want to adapt their resource plans according to their size, risk appetite, and complexity of their supply chains. The journey from the establishment of a CoE to full maturity will typically take place over one to two years, although we have seen companies move faster when they make supply chain resilience a key strategic priority.

Supply chain risk is not going away. As organizations increasingly recognize that their success depends upon their ability to manage and mitigate risk and volatility in the supply chain, many are looking for ways to strengthen their internal risk management capabilities. A supply chain risk management center of excellence is a powerful way to optimize risk management strategy, drive organizational change, and support the development of agile, intelligent, and resilient supply chains.