Supply chain visibility is the ability of stakeholders to access real-time data related to the location, movement, and state of products within the supply chain. It is an essential element of modern supply chains, connecting different stages from raw material sourcing to product delivery. This visibility is a key part of risk management, as it enables the early identification and mitigation of potential disruptions, helping businesses manage uncertainties more effectively.

Supply chain visibility is related to supply chain transparency, but the two terms are not interchangeable. Visibility refers to data that an organization uses internally to monitor, manager and optimize its supply chains. Transparency refers to supply chain data that is shared with customers, regulators, interested third parties, and other stakeholders. While companies strive to maximize the data they have on their own supply chains, for reasons of commercial sensitivity they will only share a subset of that data externally.

Why visibility matters

With globalization, supply chains have become increasingly complex and intertwined. This, coupled with the growing consumer demand for responsible sourcing, has amplified the need for supply chain visibility. Moreover, the need to comply with regulations and industry standards necessitates clear visibility into operations to ensure adherence and demonstrate accountability.

Supply chain visibility offers several benefits, including:

- Enhanced risk management

- Early identification of potential risks, enabling proactive measures to prevent disruptions

- Empowered decision-making, facilitating improved operational control.

- Stronger supplier relationships through open communication and collaboration, allowing for better supplier performance evaluation and more reliable sourcing

Supply chain visibility underpins supply chain transparency, which can help strengthen brand reputation. Consumers tend to trust businesses that are transparent about their operations, including their sourcing and manufacturing processes. and some customers insist on it. By showcasing ethical and sustainable practices in the sourcing and manufacturing operations, businesses can build a positive brand image.

And why visibility is hard

Despite its benefits, achieving supply chain visibility is not without its challenges. Collecting and managing data across various stages of the supply chain can be a daunting task. Supplier resistance and reluctance have historically posed obstacles, as not all parties may be willing to share their data. Lastly, the costs and resource constraints associated with implementing visibility measures can be a deterrent for some businesses.

Technology has a key role to play in overcoming these challenges. The power of advanced digital platforms and AI can accelerate, streamline, and automate many supply chain visibility tasks. That includes the acquisition and integration of supply chain visibility data as well as the analysis of that data to support operational and strategic decision-making.

Elements of supply chain visibility

Graph technology is emerging as an important tool for helping organizations manage risk in their supply chains. It provides a powerful way to visualize and track data, enabling companies to identify potential risks quickly and accurately.

Graph databases provide a more efficient way to query information than traditional databases, allowing companies to gain insights into the complexities of their supply chain networks with greater speed and accuracy. With graph technology, companies can easily identify hidden patterns, correlations, and anomalies that may signal a disruption or risk event. This enables them to take proactive steps to mitigate or eliminate potential problems before they arise.

Graph technology is also beneficial for understanding the relationships between different components within a supply chain network, such as suppliers and customers, production lines and products, or material types and delivery locations. By understanding these connections, organizations can pinpoint areas of weakness where risks might occur. Additionally, graph databases can be used to track changes over time so that corporations are better prepared for disruptions due to any unexpected events or developments in their supply chains.

This visibility within the supply chain can be broken down into three coverage areas: network, material flow, and logistics.

Network visibility

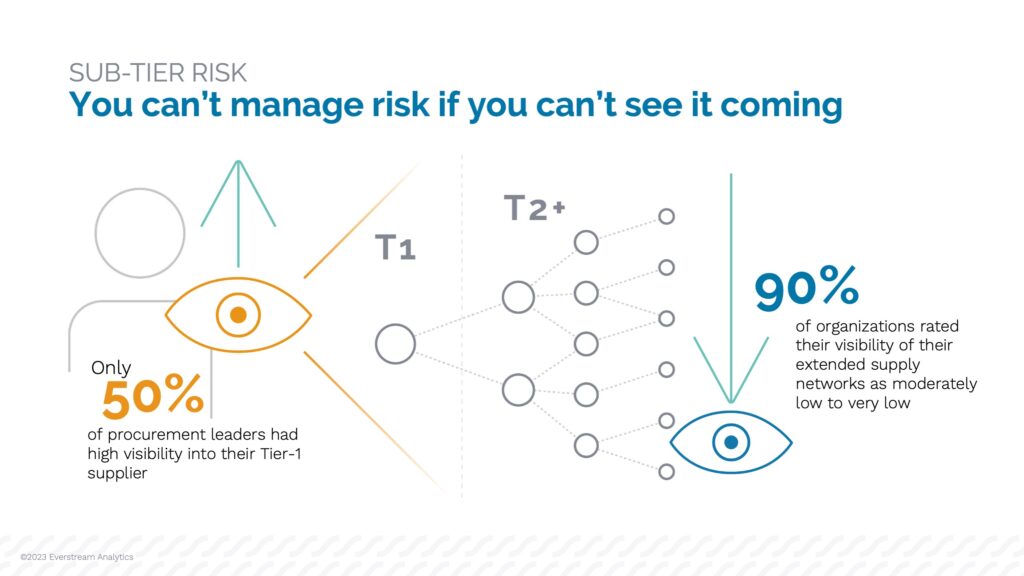

Network visibility refers to data on the location and status of supplier facilities. Many companies have a good idea who their Tier 1 suppliers are and where their operations are located. Further upstream, things are lot less clear.

Figure 1: Few supply chain leaders have supply chain visibility across their entire network.

A 2022 McKinsey survey of senior supply chain executives found that only 17% of companies had a full picture of their supply chains down to Tier 3 and beyond. In automotive, aerospace, and other industries with particularly complex supply chains, nobody was confident that that they had a good picture of their supply networks at all levels.

Effective supply chain risk management requires companies to know much more about their supply networks than a simple list of locations. They will also want to understand details of those suppliers’ operations: their compliance with health, safety, and labor standards; their policies on conflict minerals; and their cyber security and business continuity management systems to name but a few.

Network visibility can be achieved through systematic supplier validation. For example, Everstream’s supplier validation services were designed to streamline multi-tier supplier surveying with customizable data collection templates, automated distribution of requests and follow-ups, and a secure online portal where suppliers can upload and update information and supporting documentation.

Network visibility case study

One company in the medical devices sector undertook a major network visibility exercise to address supply chain risks for critical products in its portfolio. It mapped the complete supply chains for those products down to the Tier 3 and beyond, conducting a comprehensive risk assessment on those suppliers. That assessment considered a broad range of risks, from the supplier’s financial stability to likelihood of extreme weather events and even the age of the tooling in use at the supplier site.

The company used that information to make specific interventions designed to reduce risks, including identifying alternative sources supply for at-risk products and adjusting order lead times for products, such as semiconductors, which are subject to supplier capacity constraints.

Material flow visibility

Material flow visibility combines data on supplier networks with a company’s own procurement and bill-of-materials data. It allows businesses to trace the route taken by components and materials for specific products through the network. That can support initiatives including supply chain ESG, regulatory compliance, and risk scoring.

Advanced supply chain risk management tools take a holistic view of supply networks and material flows. Beyond assessing the risk exposure of critical components and individual suppliers, they are also designed to detect concentration risks. That might include large numbers of suppliers located in regions exposed to natural disasters or political instability. Or it could be hidden interdependencies in supply networks that threaten supplier diversification strategies.

Material flow case study

A European manufacturer of truck trailers uses an Everstream incident monitoring platform to manage logistics-related risks. The platform provides 24/7 near real-time alerting and feedback loops on disruption occurring anywhere in the world, and it has configured dedicated incident alerting profiles that ensure each member of the supply chain team receives only relevant alerts.

The platform also provides a feature to manually add incidents, enabling the company to quickly disseminate information about its network incidents across the organization (and not in the public domain). This user-friendly, integrated Everstream solution enables the company to track and prepare for incidents well before they become threats. The organization can now plan and arrange emergency shipments to stay ahead of the competition and maintain production so business never slows, and customer orders can be delivered on time.

Logistics visibility

Logistics visibility involves tracking the position and status of shipments and individual components in the network. Data to support logistics visibility can come from a wide range of sources, including shipment status data from logistics service providers, and vessel and aircraft tracking data collected directly from shipments equipped with wirelessly connected GPS tags.

This type of visibility supports operation supply chain risk management, by helping companies identify potential delivery delays and take appropriate mitigating actions. Those actions might include shipment rerouting to avoid logistics trouble spots, adjustments to production schedules, or redistribution of inventory to maintain the availability of cortical parts.

Everstream provides a wider range of logistics visibility tools, including real-time risk alerts for transportation-related incidents and advanced analytics systems to calculate the risk-adjusted estimated time of arrival for critical shipments.

Logistics case study

A life sciences company uses Everstream technology to support a sophisticated AI system that tracks and predicts the movement of shipments through its supply chain. The model combines around 65 different variables for each shipment, including data from millions of historical shipments, risk profiles for routes and network nodes, and real time incident alerts.

From that risk data, the risk management platform calculates the probability that each shipment will achieve its current estimated time of arrival. If the risk profile suggests that a shipment will be delayed, the model also calculates a revised estimated arrival time based upon the most current available information.

Supporting visibility in your operation

You can’t manage your supply chain if you don’t know what’s going on in it. That’s why visibility is a critical, but challenging, element of any strong supply chain management strategy.

Enhanced supply chain visibility supports enhanced risk management, early risk identification, better decision making, and stronger supplier relationships – ultimately creating a stronger and more financially stable operation.

As businesses navigate an increasingly complex and volatile world, supply chain visibility has become to be a key factor in strategic and operational risk management. The goal for every organization should be end-to-end visibility that supports planning, sourcing, manufacturing, and delivery.

To learn more download our report: Understanding Supply Chain Risk Management