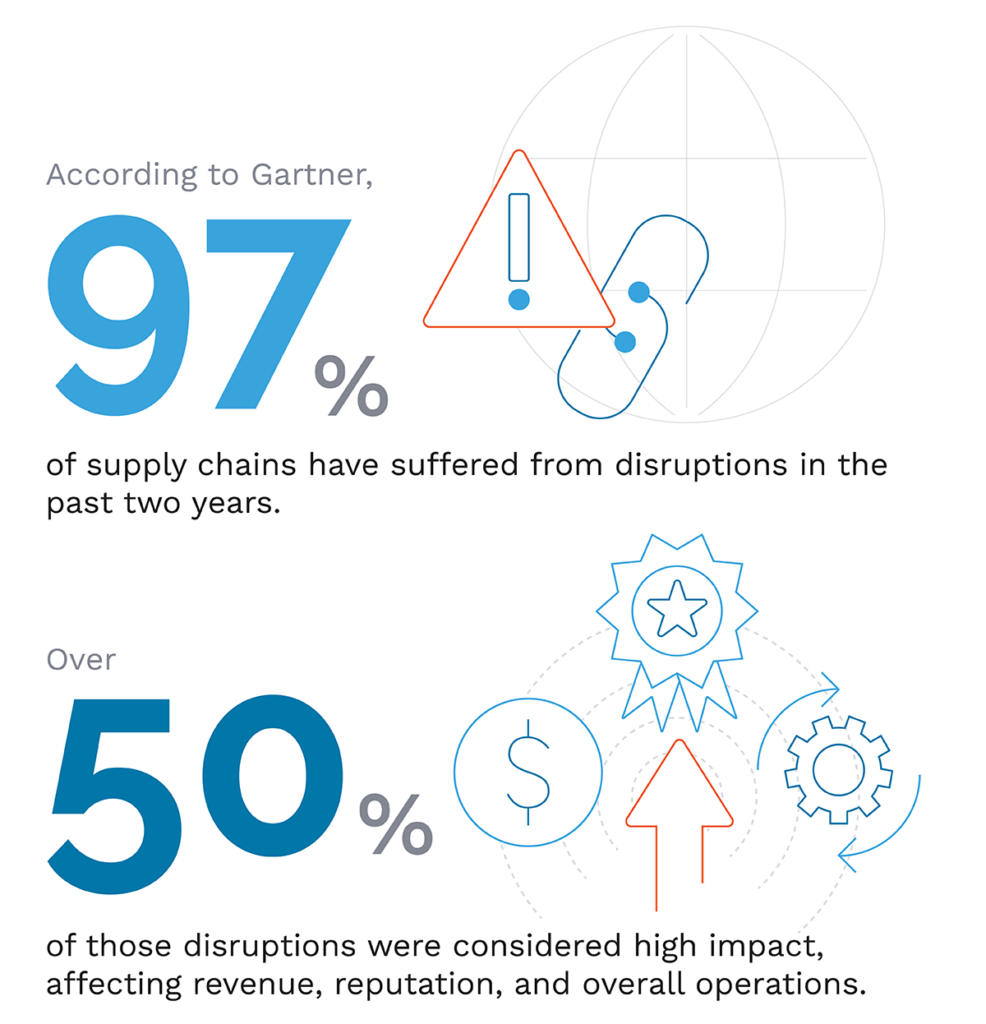

Chances are that your business has experienced at least one significant supply chain disruption over the last two years, and therefore can appreciate the benefits of adopting supply chain risk management. How did we guess, you might wonder? Well, it’s not guesswork – according to Gartner, 97% of supply chains have suffered from disruptions in the past two years. Over 50% of those disruptions were considered high impact, affecting revenue, reputation, and overall operations.

Figure 1: The risk is high – almost all supply chains experience regular disruptions, half of those being high impact.

Global supply chains are incredibly interconnected and vulnerable to a variety of growing risks. Assumptions and approximations calculated by using spreadsheets and educated guesses won’t cut it anymore. Implementing computerized supply chain risk management helps organizations make more informed decisions in the face of adverse events, creating three top benefits: saving time and money, and maintaining compliance.

Supply chain risk management’s tech shift

Supply chain risks are growing constantly in impact, scale, and complexity. Worldwide, these supply chain events have cost businesses an average of $184 million per year, according to Statista. With issues ranging from cybersecurity to natural catastrophes to regulations to the COVID-19 pandemic and more, businesses are facing a greater variety of risks than ever before. Manual tracking and forecasting is no longer even possible.

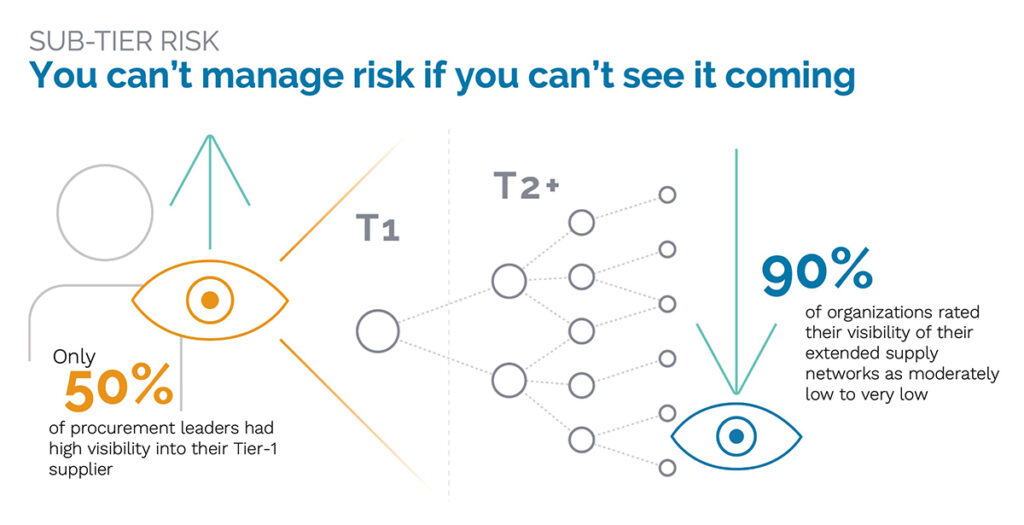

Without automated monitoring and management in place, small disruptions within a supply chain quickly snowball into substantial issues further down the supply chain. A Gartner survey revealed that 57% of companies have no immediate visibility into any incidents within their global supply chain, and are therefore unable to either act proactively or respond quickly and effectively. In fact, Everstream’s research found that only 50% of procurement leaders have high visibility into their Tier 1 suppliers, let alone throughout their supply chain sub tiers.

Figure 2: You can’t manage risk if you can’t see it coming, which most organizations don’t.

Supply chain risk management doesn’t have to be rocket science. In today’s software platforms, artificial intelligence combined with human expertise can create visibility across a company’s entire supply chain. Ongoing supply chain risk management can help your organization take proactive actions to prevent costly disruptions and minimize any downtime in the event of an incident.

Although there are multiple benefits to automated supply chain risk management (SCRM) in multiple management, operational, and finance areas, these are the top three wins cited by Everstream clients.

SCRM benefit #1: more time

Supply chain risk management creates something money can’t buy: the advantage of time.

Having immediate notification of incidents that may impact your supply chain can give your team the lead time needed to quickly implement any necessary changes within your supply chain, like switching to a back-up supplier or re-directing shipping flows. By responding quickly and efficiently – potentially even before your competitors know about or understand the impact of a given incident – your organization can minimize disruption and damages.

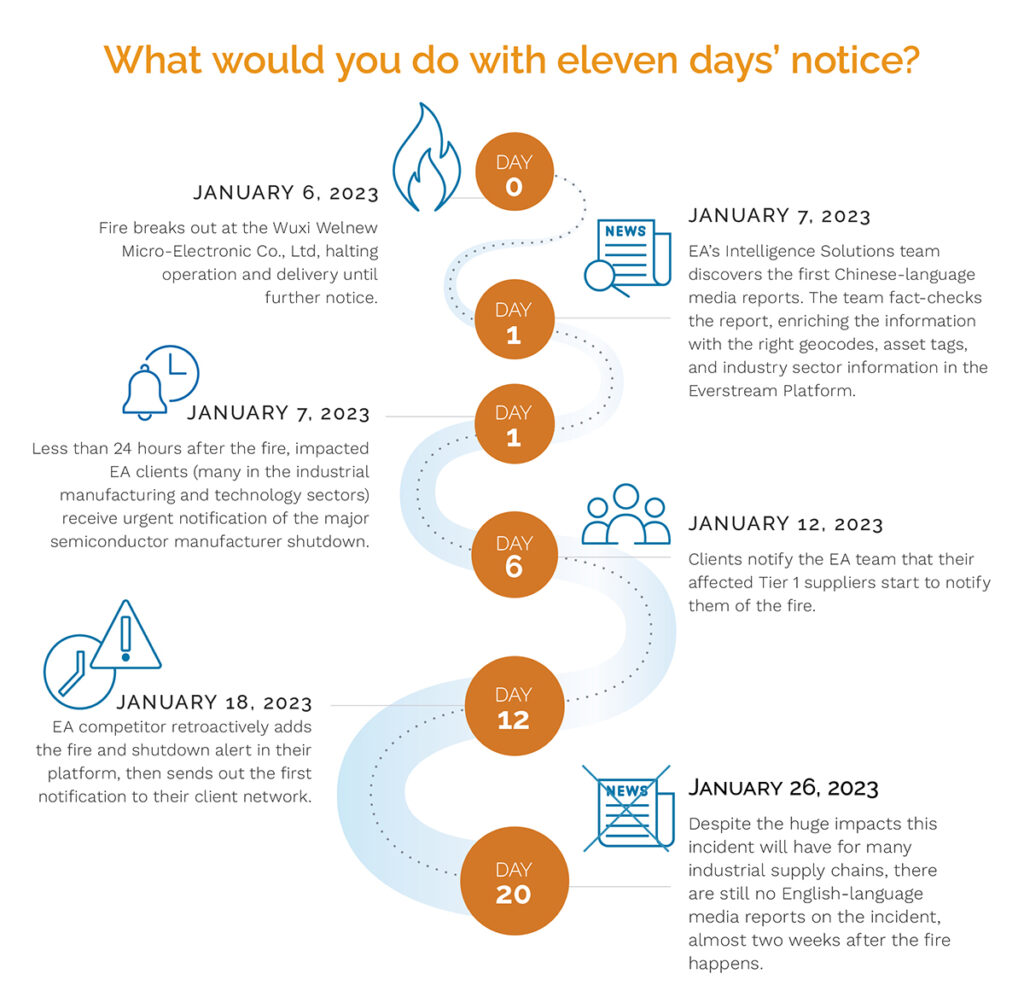

For example, in January, a fire at a major semiconductor manufacturer halted operations and deliveries until further notice. Within 24 hours, Everstream was able to notify organizations with the factory in their supply chains – even if they weren’t direct Tier 1 suppliers – giving these organizations the opportunity to act immediately. The factory itself didn’t notify their Tier 1 organizations until six days after the fire, and the incident was only reported by English-language news outlets two weeks after the fact.

By then, the semiconductor manufacturer had already ceased production and shut down, instantly impacting its immediate partners, and initiating delays across multiple industries. Organizations that didn’t have those two weeks’ notice had to scramble for alternate suppliers, reschedule shipping and freight, and make other costly .

Figure 3: One benefit of adopting supply chain risk management – early alerts for disruptive events.

However, the organizations with supply chain risk management measures in place were able to make quick, informed decisions, adjusting their suppliers and supply chain flows as necessary to minimize any losses.

SCRM benefit #2: More money

Rushed decisions rarely lead to the best fiscal options – especially if your supply chain is missing a critical element. According to the Economic Intelligence Unit, two-thirds of surveyed companies reported up to 20% of revenue damage over the past year due to supply chain incidents. Preparing for these incidents by implementing supply chain risk management can help minimize these revenue hits and even lead to larger cost savings.

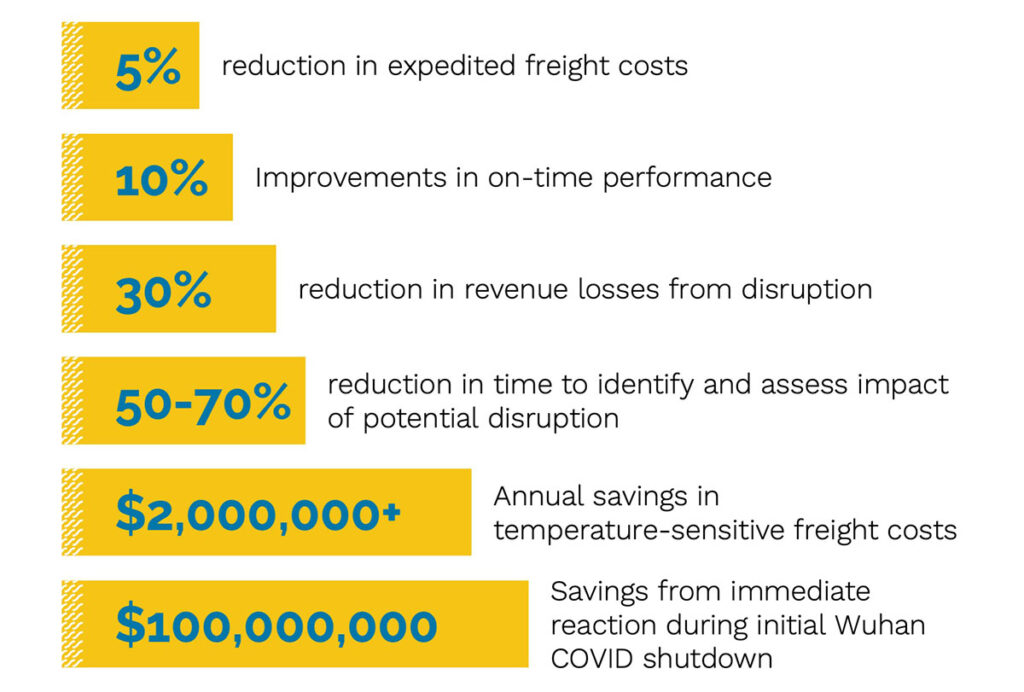

Supply chain risk management effectively gives organizations the ability to adjust more quickly to supply chain flows, creating significant cost savings. Using advanced technology and analytics to help organizations build supply chain risk management systems, Everstream has observed a 5% decrease in expedited freight costs and a 30% decrease in revenue losses from disruptions.

Figure 4: Financial and operational benefits of adopting supply chain risk management include time and money savings.

Plus, understanding the risks inherent in an organization’s supply chain can also help in optimizing operations, leading to ongoing cost reductions. For example, organizations that ship temperature-sensitive products report having saved over $2 million using Everstream’s supply chain risk management platform. With access to up-to-date weather models and other pertinent information, these organizations can plan effectively to ensure that freights are properly protected against inclement weather conditions, leading to fewer frozen, unusable products. Likewise, these organizations are also able to detect when temperature-controlled vehicles may be unnecessary, and apply cost-saving measures accordingly.

SCRM benefit #3: easier compliance

Knowledge is power. Understanding the risks within a supply chain can make the difference between an organization that ensures sustainability across their supply chain, complies with relevant legislation and regulations, and is trusted by customers versus an organization with a damaged reputation due to poor risk management. Supply chain risk management is key to creating and maintaining a strong, trusted brand.

Customers and governing bodies alike are becoming increasingly aware of sustainability and human rights issues within supply chains, and are demanding corporations to improve conditions around the world. An organization’s reputation can be seriously damaged by poor sustainability policies, even if the issue is found deep within the supply chain and not directly at the organization. Customers are beginning to avoid organizations with poor sustainability track records and may look to competitors instead.

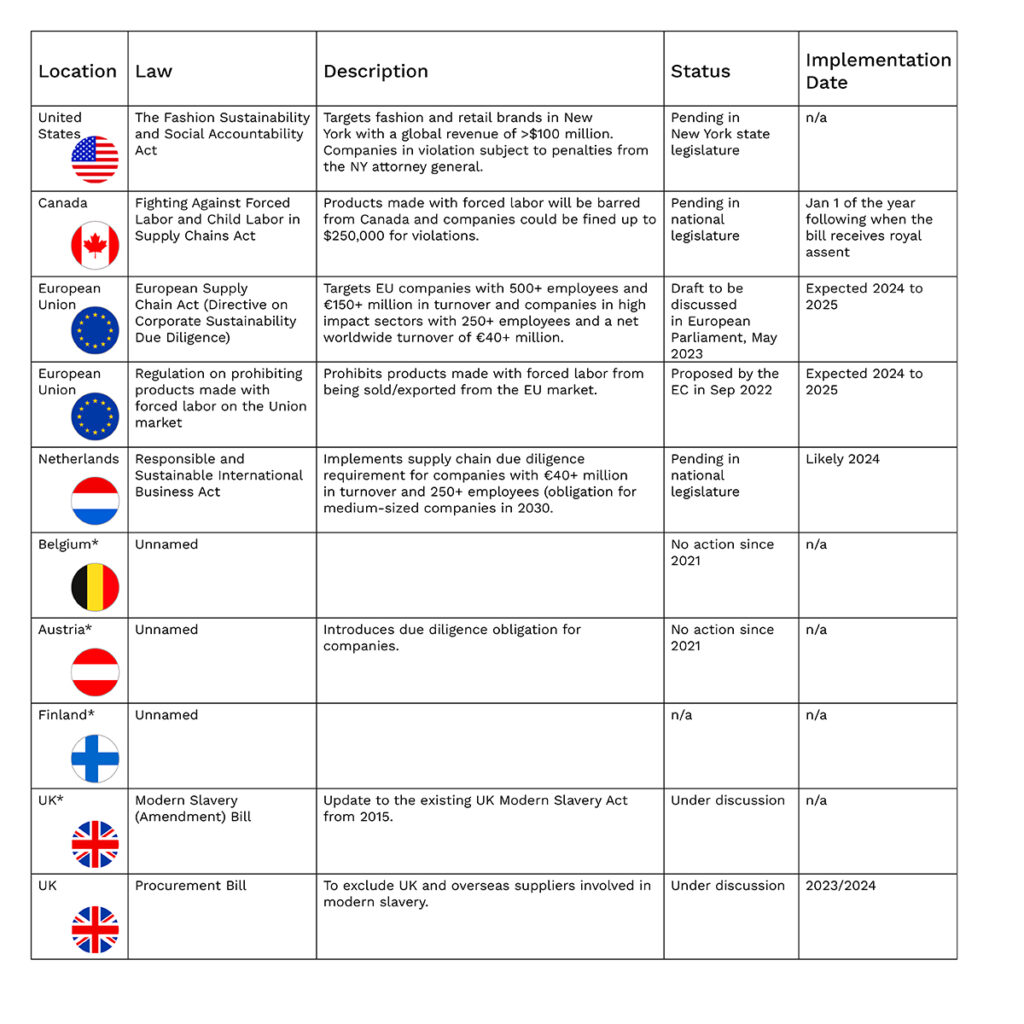

Furthermore, organizations that don’t comply with relevant regulations and legislations may be at risk of costly fines. Recent laws such as the U.S.’s Uyghur Forced Labor Prevention Act (UFLPA) and the EU’s Supply Chain Act both require organizations to take responsibility not only for their own actions, but for the actions of their suppliers. The consequences can be expensive; the US’s Customs and Border Protection has already seized over $800 million worth of goods due to non-compliance with the UFLPA, which went into effect less than a year ago. Without visibility into an organization’s entire supply chain, it is very difficult to recognize and mitigate these sustainability risks.

Figure 5: Countries worldwide are seeing benefit in adopting supply chain risk management laws.

By implementing automated supply chain risk management, organizations can monitor the relevant human rights and environmental issues that may be present within their global supply chain, and adjust them before facing troublesome consequences.

Additional benefits to adopting supply chain risk management

These top three benefits aren’t the only payoffs from automated risk management. Other wins come from ease of integration into existing software systems, filtering through the noise to pinpoint only relevant alerts, and the ability to leverage predictive insights.

Supply chain risk management is key to creating flexible, resilient operations. Organizations that implement risk management will be able to take proactive action against potential or unavoidable risks, saving time, money, and more.

By giving organizations the benefit of time to make considered decisions, providing cost-savings opportunities, and helping maintain compliance, supply chain risk management is now table stakes for organizations operating in our increasingly complex and interconnected global marketplace.

Get the framework in our eBook to calculate what your operation could save using SCRM